Products

Contact Us

Mobile:+8613994825542 +8613994827332

Telephone:+863583912665

E-mail:lyq@sxxrdyj.cn

Address: Xifenyang Village Industrial Park, Jiaocheng County, Shanxi Province

Ingot mould

Key words:

Classification

Introduction

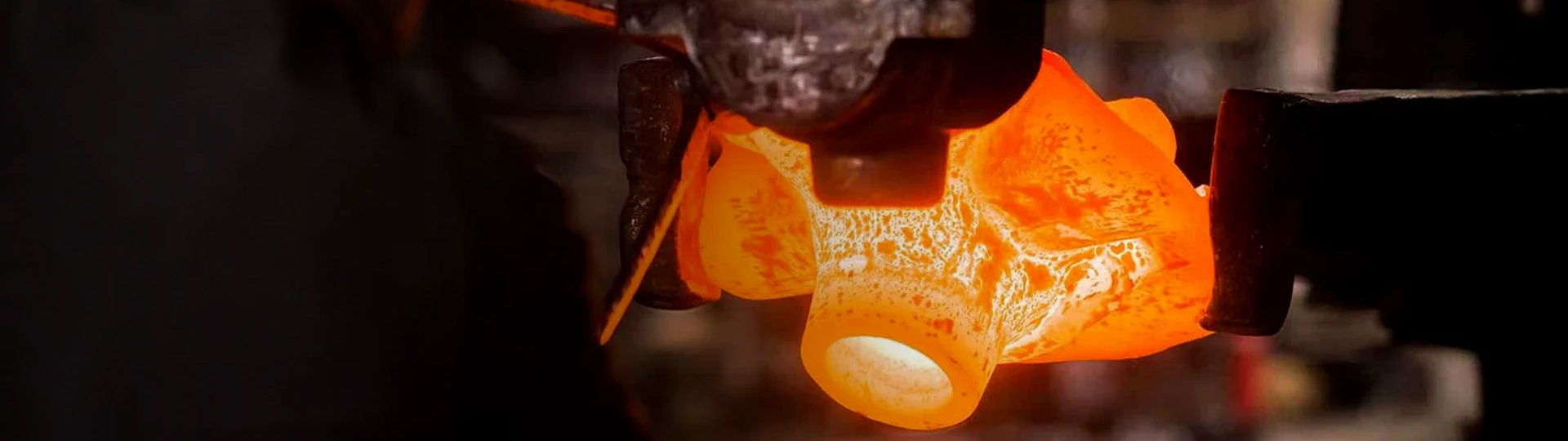

1. Product Overview

Ingot mold, as the key equipment in the metal smelting industry, is mainly used for casting various metal ingots, such as steel ingots, copper ingots, aluminum ingots and so on. Our well-designed ingot mold has established a good reputation in the industry for its excellent performance, reasonable structure and long service life.

2. material and process

- High quality material: We choose high-strength, high-heat-resistant alloy steel as the main material of the ingot mold to ensure that it still maintains stable performance under high temperature environment.

- Exquisite craftsmanship: After precision casting, heat treatment, machining and other processes, we ensure that the dimensional accuracy, surface quality and internal organization of the ingot mold reach the optimal state, thereby improving its service life and casting efficiency.

3. product features

- High strength and heat resistance: High-quality alloy steel materials and special heat treatment processes give the ingot mold excellent strength and heat resistance, ensuring that it is not easy to deform or damage during high-temperature casting.

- Good thermal conductivity: The ingot mold has reasonable design and good thermal conductivity, which can quickly transfer heat to the molten metal and improve the casting efficiency.

- Long life and easy maintenance: The ingot mold made of high-quality materials and exquisite craftsmanship has a long service life, and is easy to maintain and maintain, reducing the user's operating cost.

- High accuracy: We strictly control the manufacturing process of the ingot mold to ensure that its dimensional accuracy and surface quality reach the highest standards, so as to ensure that the cast ingot has high quality.

4. scope of application

This ingot mold is widely used in iron and steel, non-ferrous metals and other metal smelting industries to meet the casting needs of various metal ingots. Whether it is a large steel company or a small smelter, we can provide the right ingot mold solution.

5. Quality Assurance

We always adhere to the principle of quality first, from raw material procurement to production and processing, and then to quality inspection, every link is strictly controlled to ensure that the quality and performance of the ingot mold meet national standards and user needs. At the same time, we provide perfect after-sales service and technical support to ensure that users get timely and effective help during use.

Reasons 6. choose us

- Professional manufacturing: We have many years of ingot mold manufacturing experience and technology accumulation, and can provide users with high-quality products and solutions.

- high quality quality: We pay attention to the improvement of product quality and performance, and constantly optimize the material formula and manufacturing process to ensure that the ingot mold has excellent performance and long service life.

- Perfect service: We provide comprehensive pre-sales consultation, in-sales support and after-sales service to ensure that users receive timely and effective help and support during use.

7. immediate action

If you are interested in our ingot mould products, or have any questions or needs, please feel free to contact us. We look forward to working with you to create a better future!

Previous article:

The next one:

Related Products

immediate consultation